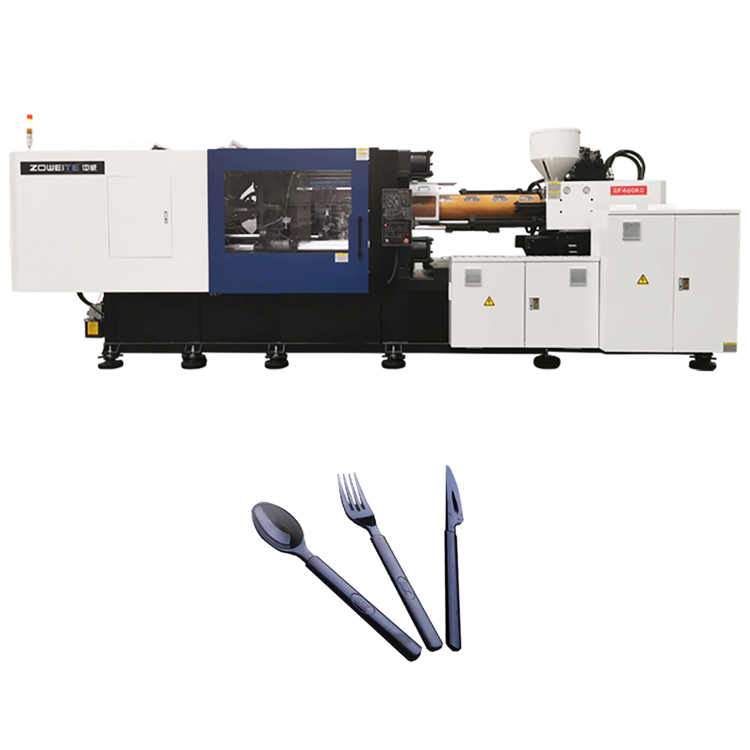

High Speed Injection Molding Machine

A high-speed injection molding machine is a specialized type of injection molding machine designed for rapid and efficient production of plastic parts. It is engineered to provide faster cycle times, shorter cooling periods, and increased productivity compared to standard injection molding machines.......

Send Inquiry

Product Description

A high-speed injection molding machine is a specialized type of injection molding machine designed for rapid and efficient production of plastic parts. It is engineered to provide faster cycle times, shorter cooling periods, and increased productivity compared to standard injection molding machines. Here are some key features and benefits of high-speed injection molding machines:

1. Accelerated Injection Speed: High-speed machines are equipped with advanced hydraulic or electric drive systems that enable rapid injection of molten plastic into the mold. They can achieve significantly higher injection speeds compared to conventional machines, reducing the cycle time and increasing production output.

2. Quick Response and Precision: High-speed machines incorporate advanced control systems and servo-driven technology, allowing for precise control over the injection process. This enables quick response times, accurate dosing of material, and tight control over injection parameters, resulting in consistent part quality.

3. Fast Cooling and Shorter Cycle Times: High-speed machines are designed to optimize cooling efficiency through enhanced cooling circuits, efficient heat transfer, and precise temperature control. This enables faster solidification of the plastic part, reducing the cooling time and overall cycle time. Shorter cycle times lead to increased production capacity and lower per-unit costs.

4. Enhanced Automation and Robotics Integration: High-speed injection molding machines often integrate seamlessly with automation and robotics systems. This enables automated part handling, insert loading, and post-molding operations, further optimizing production efficiency and reducing labor requirements.

5. High Productivity and Cost Efficiency: The combination of faster cycle times, increased production output, and improved energy efficiency makes high-speed injection molding machines highly productive and cost-effective. They allow for efficient utilization of resources, reduced energy consumption, and improved overall manufacturing efficiency.

6. Suitable for Thin-Wall and Precision Parts: High-speed machines are particularly well-suited for producing thin-wall parts and precision components that require short molding cycles and high injection speeds. These machines can achieve precise filling and packing of the mold, ensuring uniform part thickness and dimensional accuracy.

7. Process Monitoring and Control: Advanced high-speed injection molding machines are equipped with comprehensive process monitoring and control systems. These systems enable real-time monitoring of process parameters, detection of abnormalities or defects, and automatic adjustment of machine settings to maintain consistent part quality throughout the production run.

High-speed injection molding machines find applications in various industries, including packaging, consumer electronics, automotive, medical devices, and more. They are commonly used for manufacturing thin-wall containers, caps, closures, electronic components, and other high-volume, high-precision parts.

It's important to note that high-speed injection molding requires careful consideration of material selection, mold design, and process optimization to ensure optimal results. Proper training and expertise are necessary to maximize the benefits and capabilities of high-speed injection molding machines.